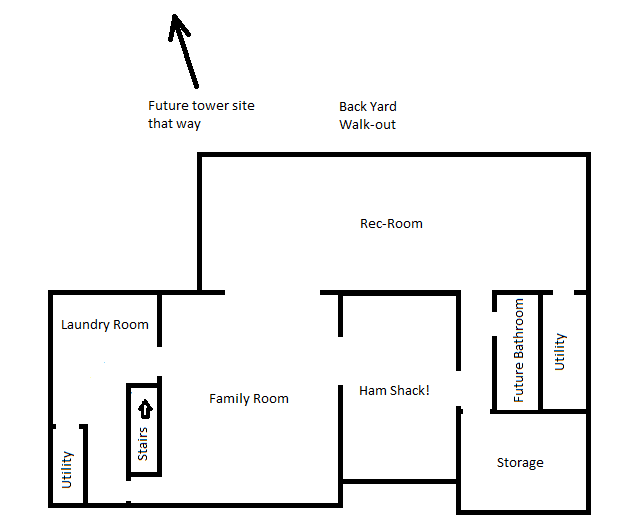

In my last post I mentioned several things I was planning, and these were precisely the things I ended up getting done. The first thing I put in was some empty conduit, because even though I am pulling stuff through now, it's hard to anticipate future needs. In one section the fit was tight, so 1" conduit was the widest I could put in without a lot of concrete busting. Because of that I made 2 runs side by side, from the back wall of the shack, to an access box that I installed in the back wall of the walk-out basement.

Next up was the coax. I ordered enough Times Microwave LMR-400 from DX Engineering to pull 4 runs across the space. As a side note here, DX Engineering means business with their shipping! My order was big enough to get the free shipping, and it was almost 24 hours on the nose from the time I ordered it till the time it was sitting on porch - impressive! I ordered the coax in bulk, so I rolled it out lengthwise down the long stretch of the rec-room to cut it into 4 sections.

In addition to the coax, I also ordered enough for a single run of control cable, anticipating a rotor at some point in my future. Finally, I knew I wanted some network cable running from the shack to the tower for potential future uses, so (at the suggestion of a couple different folks) I cut 2 lengths of that as well. With all these cables cut to length, I tacked up the coax right above the conduit runs, and the control cable and network cables to the other side of the joist bay.

In a separate area I also pulled a run of 12-2 Romex from the sub panel in the shack, to a location that I can get to from the outside. My thought here is that if I end up needing power at the tower, I have a line ready for it, powered from the same source as everything else in the shack.

As hard as it is to do, the next step was to stuff the insulation back in place, and hide all of my hard work!

So with all this stuff done, I'm ready to start closing up the walls. When I eventually do put up the tower, I'll be able to take the cover off this box, roll the coax and cables out of the way, and drill straight through the back of the box and the exterior wall, to put a conduit to an entrance panel right on the other side of this wall, with runs out to the tower. easy-peasy!

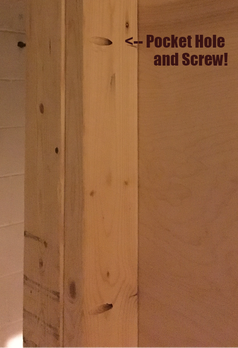

Next step, drywall. I've never hung drywall before, but I decided it was finally time for me to try and tackle it on my own. I won't be working in the blind though - I have a brother-in-law that hangs and finishes drywall, and a neighbor that used to work for a large drywall distributor, so I'll be leaning on their expertise pretty hard. If you see anything I missed that you think I should do before I close things up, or if you have any drywall tips, please feel free to leave me a comment - It'll be a few days before I get started, and tips are always welcome!

RSS Feed

RSS Feed